BBLS INJECTED TO DATE

BBLS/DAY CAPACITY

Safe, Sustainable Oil and Gas Waste Disposal in Karnes County

Operating out of Karnes County in the heart of the Eagle Ford Shale, Advantek® Waste Management Services utilizes our patented slurry injection techniques to safely and permanently sequester waste from oil and gas operations with no surface liabilities and the smallest possible footprint to maximize environmental and economic sustainability.

Located just off of US-72 outside Kenedy, Texas, Advantek Waste Management Services is strategically located to minimize waste transport logistics for oil and gas companies across the Eagle Ford Shale.

Our Karnes County injection well delivers a permanent and environmentally friendly solution to the disposal of complex oil and natural gas wastes from drilling, completion, and production operations, monitored in real-time by our proprietary @SSURE® injection well monitoring software to ensure zero surface liabilities.

Kenedy

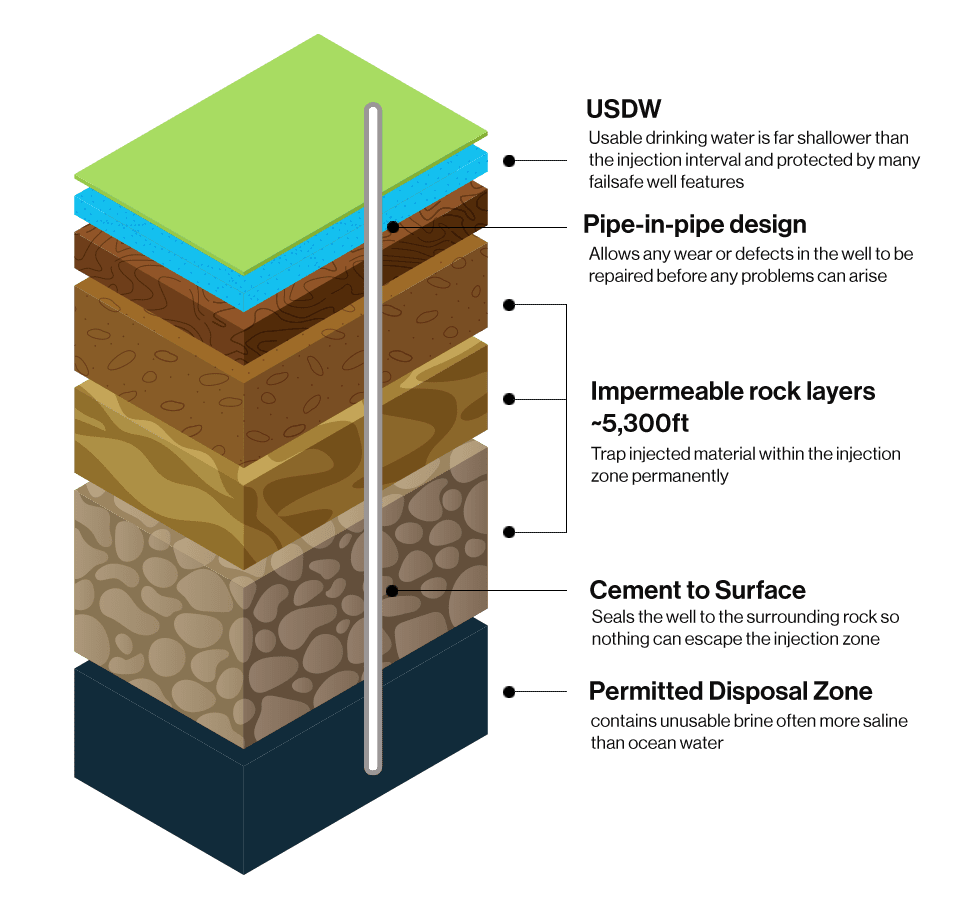

CLASS II Deep Injection Well

An Inside Look at Karnes County Facility

Well

Reed #1

Depth

6,400-6,655 ft

Capacity

25,000 bbls/day

Pipeline

3,500 bbls / day for

produced water

Wastes Sequestered

UIC Class II (RCRA Exempt)

- Cement returns

- Flowback water

- Muds

- Pit waste

- Premium washouts

- Produced water

- Tank bottoms, etc.

A Permanent Solution for Managing Complex Waste

Selecting a site for an injection well requires balancing the subsurface, surface, and logistical considerations, and matching them to the waste type, equipment and financial requirements for the project.

The Experience and the Expertise

Our engineers and operational teams have the expertise to design and manage injection projects from start to finish with best practices acquired over decades.